Parvath Tech | Explore the Energy | Research & Development

EMS Test Bench

Modern engines have more sensors and actuators for improved performance, efficiency, and emission management. Therefore, apart from reading the working principles theoretically, it is essential to comprehend the workings of these sensors and actuators in more depth and how they help meet engine requirements in different driving conditions.

The Engine Management System (EMS) Test Bench was developed based on this objectivity. Through this EMS test bench, any engineer can simulate and investigate real-time engine behavior.

Wankel Engine Control Unit

The Wankel Engine Control Unit (ECU) for UAVs and Drones exerts comprehensive control over electronic injection and ignition systems. The fuel control system demonstrates precision in managing injection duration, initiation, and compensation for factors such as air temperature, air pressure, altitude, engine temperature, battery voltage, acceleration, cold start-ability, and idling.

Simultaneously, the ignition control system exhibits precise control over ignition time, dwell time, and dwell time compensation, accommodating variations in engine temperature and battery voltage.

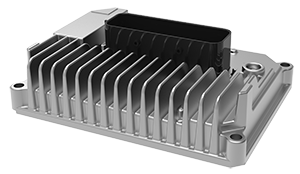

Open ECU

Parvath Tech takes pride in crafting Open Electronic Control Units (ECUs) designed for full customization to meet unique requirements. Our end-to-end, in-house development encompasses hardware, firmware, and application software, offering a comprehensive solution for your automotive needs.

GDI Control Unit

The Gasoline Direct Injection (GDI) Control Unit configuration incorporates a single-piston GDi fuel pump with an integrated control solenoid, rail pressure sensor, and fuel injector to generate a high-pressure spray.

A motor-driven cam lobe activates the pump’s plunger and piston, with an integrated pressure control solenoid regulating the solenoid valve closure at specific cam lobe angles to achieve the desired fuel pressure.

The control unit, informed by inputs from the cam encoder and fuel rail pressure sensor, determines the timing and duration for closing the pump’s control solenoid. Concurrently, the fuel injector, under the control unit direction, delivers the fuel spray for the required duration.

Customizes HIL Test Bench

Our HIL (Hardware-in-the-Loop) test bench is a crucial tool in ensuring the real-time behavior of systems during development. At Parvath Tech, we specialize in creating customized test benches tailored to specific requirements. This bespoke approach allows for effective proof of concept and result validation before transitioning to the actual system.